- BAHAY

-

MGA PRODUKTO

-

Pinagsama-samang mga Circuit

- IC para sa Xilinx

- IC para sa Brondcom

- IC para sa Texas Instruments

- IC para sa Intel/Altera

- IC para sa STMicroelectronics

- IC para sa Infineon

- IC para sa Microchip

- IC para sa mga Analog na Device

- IC para sa NXP Semiconductor

- IC para sa Realtek

- IC para sa ON Semiconductor

- IC para sa Maxim Integrated

- Mga bahagi para sa Micron

- IC para sa Giga Device

- IC para sa Winbond

- IC para sa SG Micro

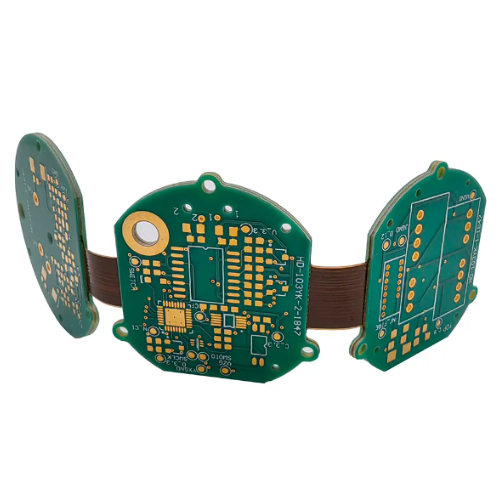

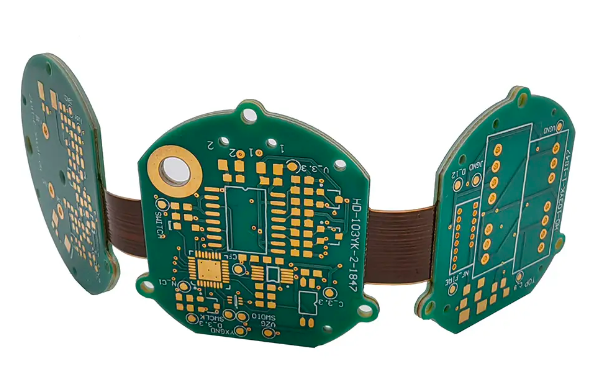

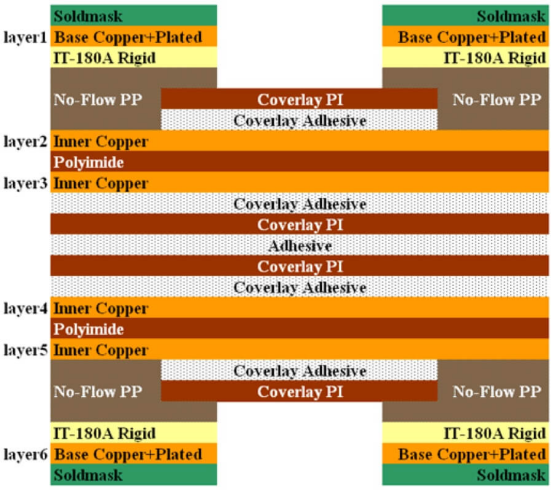

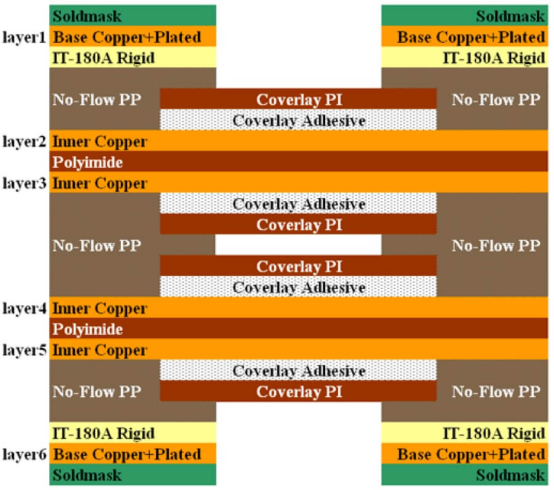

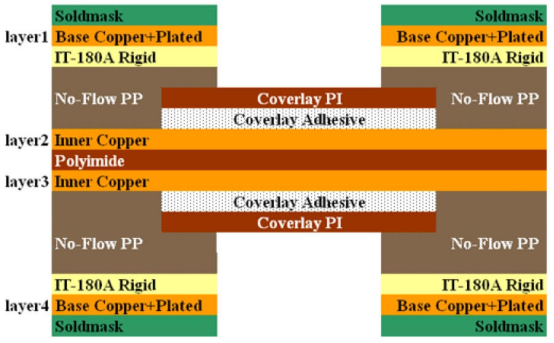

- PCB at PCB Assembly

-

Pinagsama-samang mga Circuit

- SERBISYO

- TUNGKOL SA ATIN

- PAGBILI NG BOM

- BALITA

- MAKIPAG-UGNAYAN SA AMIN

Pilipino

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski Српски

Српски 简体中文

简体中文 繁體中文

繁體中文 Беларус

Беларус